Home > Resource Center > News > Technical articles > Bullseye Intelligent four-way shuttle leads the new trend of the cold chain industry and realizes the innovation of automated three-dimensional warehousing

Home > Resource Center > News > Technical articles > Bullseye Intelligent four-way shuttle leads the new trend of the cold chain industry and realizes the innovation of automated three-dimensional warehousingIn the tide of intelligence and automation, the Bullseye Intelligent four-way shuttle is leading a new trend in the cold chain industry with its unique technical advantages. As the core part of the Shanghai cold chain project, the four-way shuttle three-dimensional warehouse has been put into use, which has improved the efficiency and floor area ratio of intelligent warehousing to a new height.

As a member of the automation equipment, the Bullseye Intelligent four-way shuttle upgrades the traditional plane movement mode to a four-way shuttle, which greatly improves the storage and retrieval efficiency of goods. This smart device can flexibly shuttle in a narrow space to complete the tasks of inventory and pick-up, which greatly improves the space utilization and operation efficiency of the warehouse.

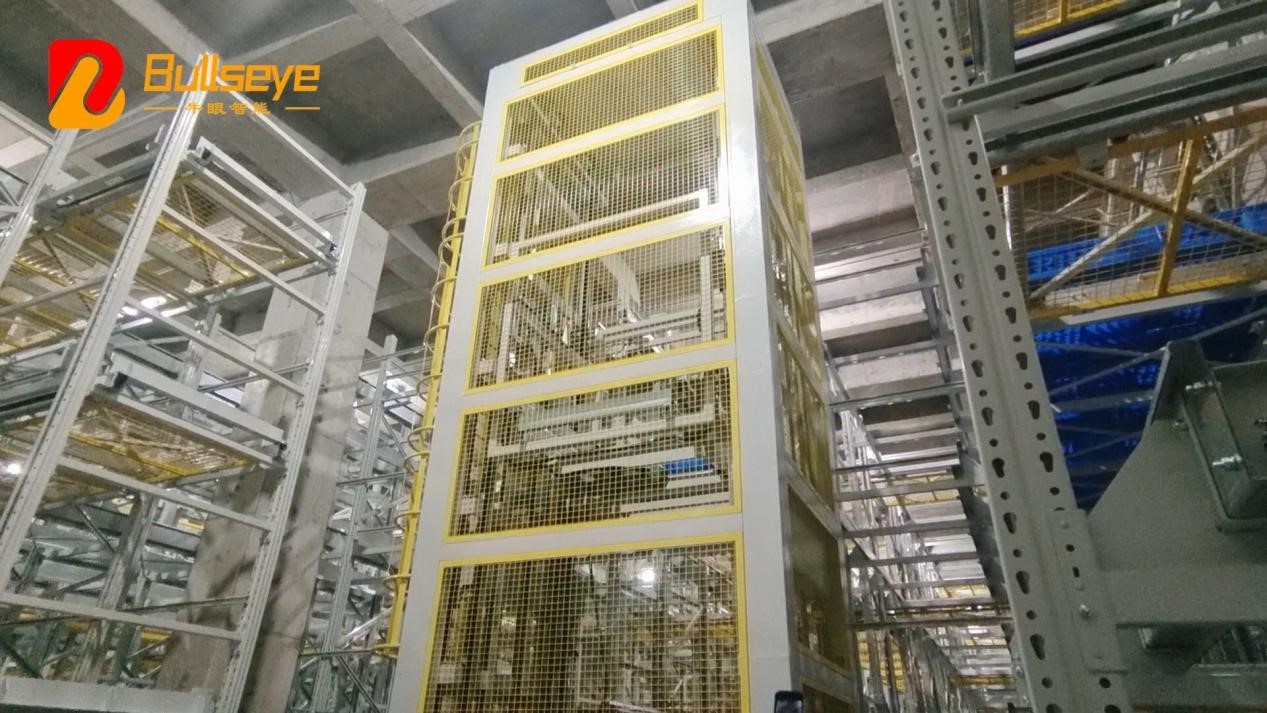

In this project, we see the great potential of automated three-dimensional warehouses. Through the introduction of 8 four-way shuttles and 3 hoists, the warehouse height is nearly 7 meters, the number of cargo spaces is 3,180, and the inbound and outbound efficiency reaches 60 pallets/hour. Compared with traditional warehouses, its floor area ratio has been increased by 200%, and the efficiency of warehousing has been increased by 180%.

It's a warehousing revolution. Under the guidance of Bullseye Intelligent, the traditional cold chain industry has taken a solid step on the road of automation and intelligence. The successful application of the four-way shuttle three-dimensional warehouse has set a new benchmark for the entire industry and demonstrated the huge potential of intelligent warehousing. In the future, Bullseye will continue to adhere to technological innovation and endow more equipment with intelligent capabilities, in order to demonstrate the powerful power of automated three-dimensional warehouses in more fields and more projects.