Home > Resource Center > News > Company news > Preview: Bullseye Intelligence was invited to participate in the 17th International Food Cold Chain Summit Forum

Home > Resource Center > News > Company news > Preview: Bullseye Intelligence was invited to participate in the 17th International Food Cold Chain Summit ForumOn June 21, 2024, the 17th International Food Cold Chain Summit Forum will be held in Shanghai. This forum will be themed "New Food Era - Safety and Efficiency" and will invite more than 460 guests from industry experts, brand company executives, and excellent solution providers to attend the event.

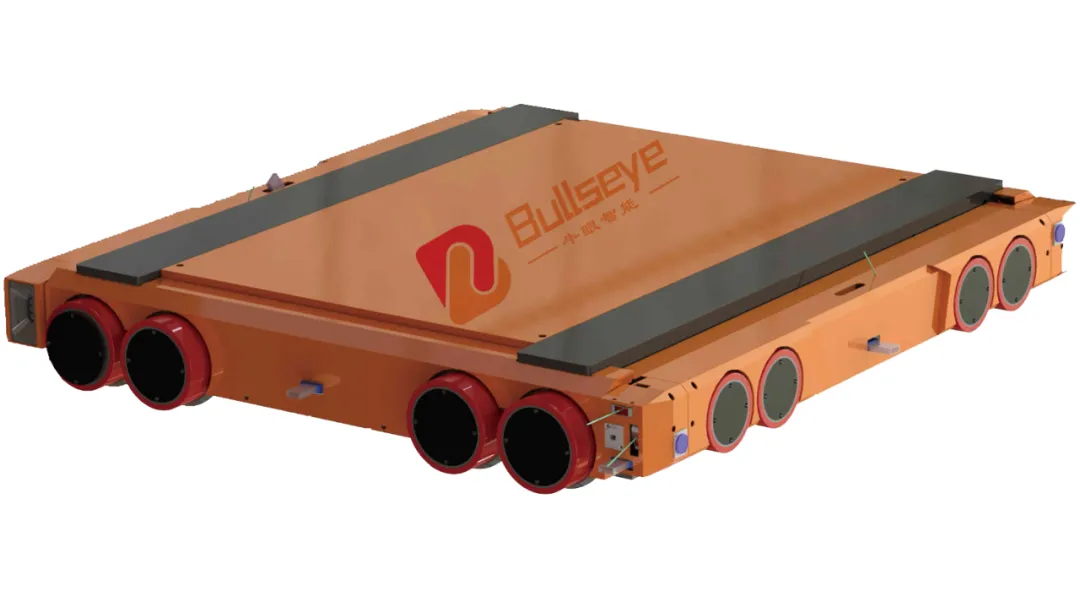

With the continuous development of the food industry, customers' demand for intelligent cold chain warehousing is also increasing. Niuyan Intelligence has been deeply engaged in the field of warehousing robots, insisting on customer-centricity, constantly innovating technology and improving services to meet customers' needs for "safer and more efficient". The cold storage type four-way shuttle robot currently developed independently can operate normally in an environment of -25℃.

At the summit forum, Mr. Liu Bin, Sales Director of NiuYan Intelligent, will take "Intelligent Cold Chain Technology Integrated Service" as the theme, and elaborate on how to provide customers with efficient intelligent logistics solutions through forward-looking logistics planning, advanced automation equipment and logistics information systems.

NiuYan Intelligent always takes customers as the center, strives to serve more users, and jointly achieve the future!

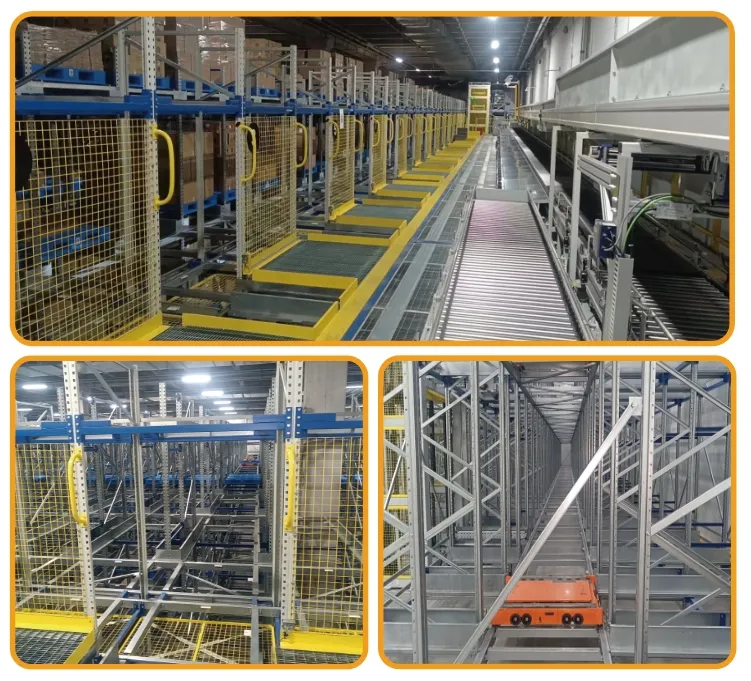

Food cold chain industry case - a food cold storage in Shanghai

Customer pain points:

·Lack of batch management of goods

·The cold storage environment has higher requirements for logistics equipment

Bullseye Smart Implementation Plan:

·Warehouse height: 7m

·Equipment quantity: 8 four-way vehicles, 3 hoists

Project value:

·Total number of cargo spaces: 3180

·The plot ratio increased by 200%

·The total number of inbound and outbound cargoes is 120 pallets per hour, and the efficiency of inbound and outbound cargoes has increased by 180%.

Food cold chain industry case - a beverage warehouse in Hangzhou

Customer pain points:

·Finished products are stacked in a single layer, which does not fully utilize the three-dimensional space.

·The in and out registration is complicated, inefficient and inaccurate, and intelligent management is needed

·Two fire zones are set up, and cross-regional operations and pallet compatibility issues need to be considered

Bullseye Smart Solutions:

·Warehouse height:9m

·Number of devices:24 four-way vehicles, 7 elevators

Project value:

·Total number of cargo spaces: 7230

·The plot ratio increased by 160%

·The total number of inbound and outbound cargoes is 270 pallets per hour, and the efficiency of inbound and outbound cargoes has increased by 300%.