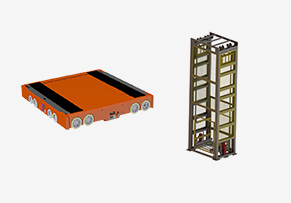

According to the different loads of the four-way shuttle, it is mainly divided into two categories: tray type four-way shuttle and box type four-way shuttle. These two types of four-way shuttle cars are basically similar in terms of structure and operation, both of which attach great importance to key skills such as control, communication, positioning, scheduling, and rapid improvement. However, there are differences in detail design and usage scenarios.

Box type four-way shuttle car

The use time of the box type four-way shuttle is about 10-15 years later than that of the multi-layer four-way shuttle, and it was applied in the European market around 2013.

Pallet four-way shuttle car

The tray four-way shuttle also originated in Europe. It is reported that the tray four-way shuttle was first developed by the Swedes, mainly including a two-way tray shuttle system, a parent-child shuttle system, and a two-way shuttle+stacking frame system. During this period, the two way pallet shuttle was gradually accepted in the Chinese market in 2009. Due to the fact that the two-way shuttle can only use "first in, first out" or "first in, first out" forms when loading and unloading goods, its early use was limited to large quantities and few varieties of goods. However, with the development of the market, the demand for small batch and multi frequency storage of goods is increasing day by day. At the same time, due to factors such as rising land costs, users have an increasing demand for space conservation and intensive storage. In this context, a tray four-way shuttle vehicle that integrates dense storage, space saving, and flexible scheduling has emerged.

Bullseye Intelligent Logistics Equipment (Suzhou) Co., Ltd. is a national high-tech industry that integrates product research and development, manufacturing, sales, planning, design, implementation, and after-sales, providing customers with one-stop intelligent warehousing and logistics automation services. Bullseye Intelligent is committed to expanding the field of intensive storage robots. Its independently developed four-way shuttle tray has been maturely applied in industries such as 3PL, retail, cold chain, manufacturing, e-commerce, and fast-moving consumer goods, and has received recognition and praise from a large number of users.